Two cylinder heads were removed for examination at 190 hours. The heads are liquid cooled and were examined to see the results of 200 hours of run time with special attention to the exhaust valves. Here are the results with some comentary. 9/27/21

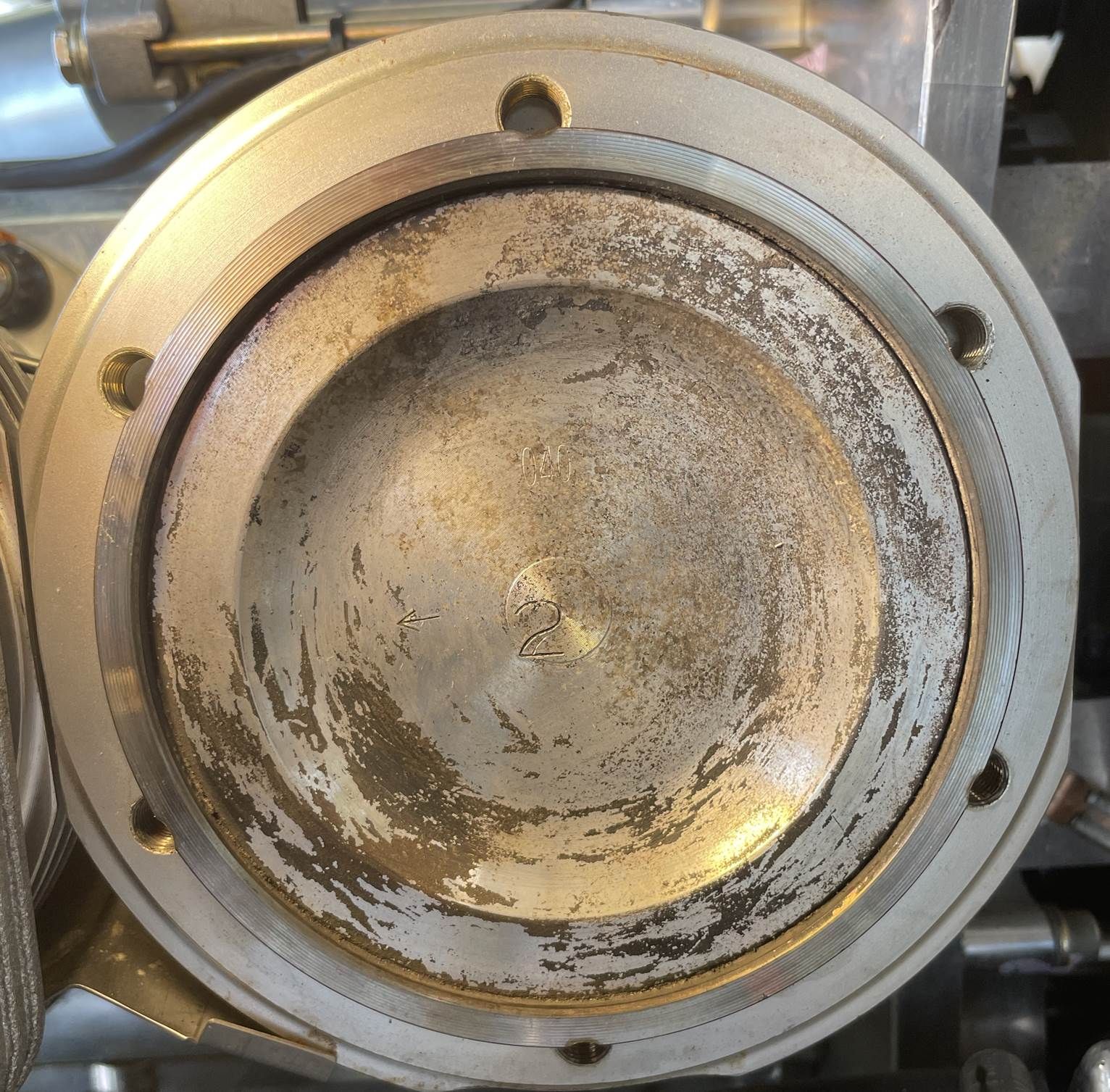

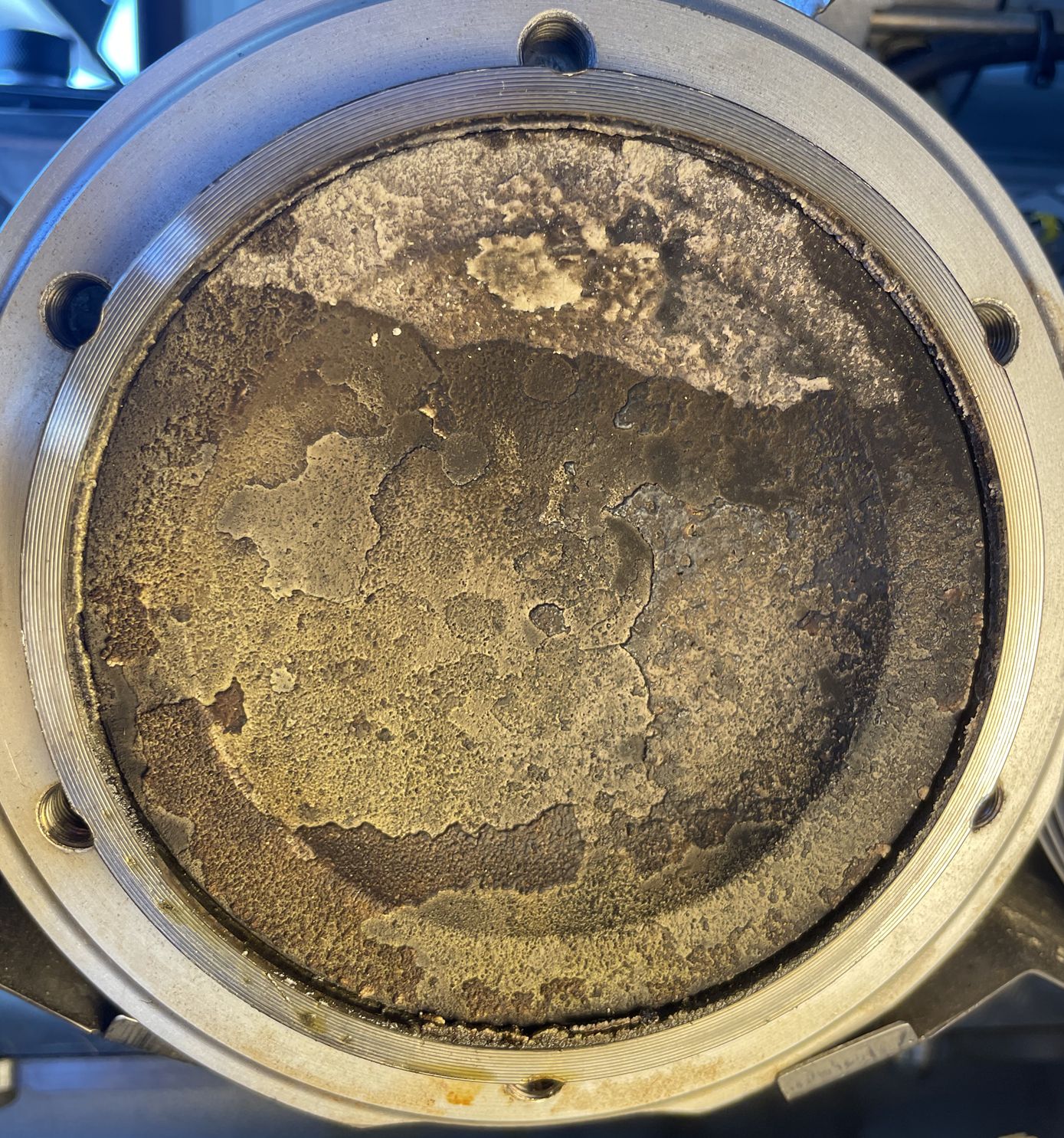

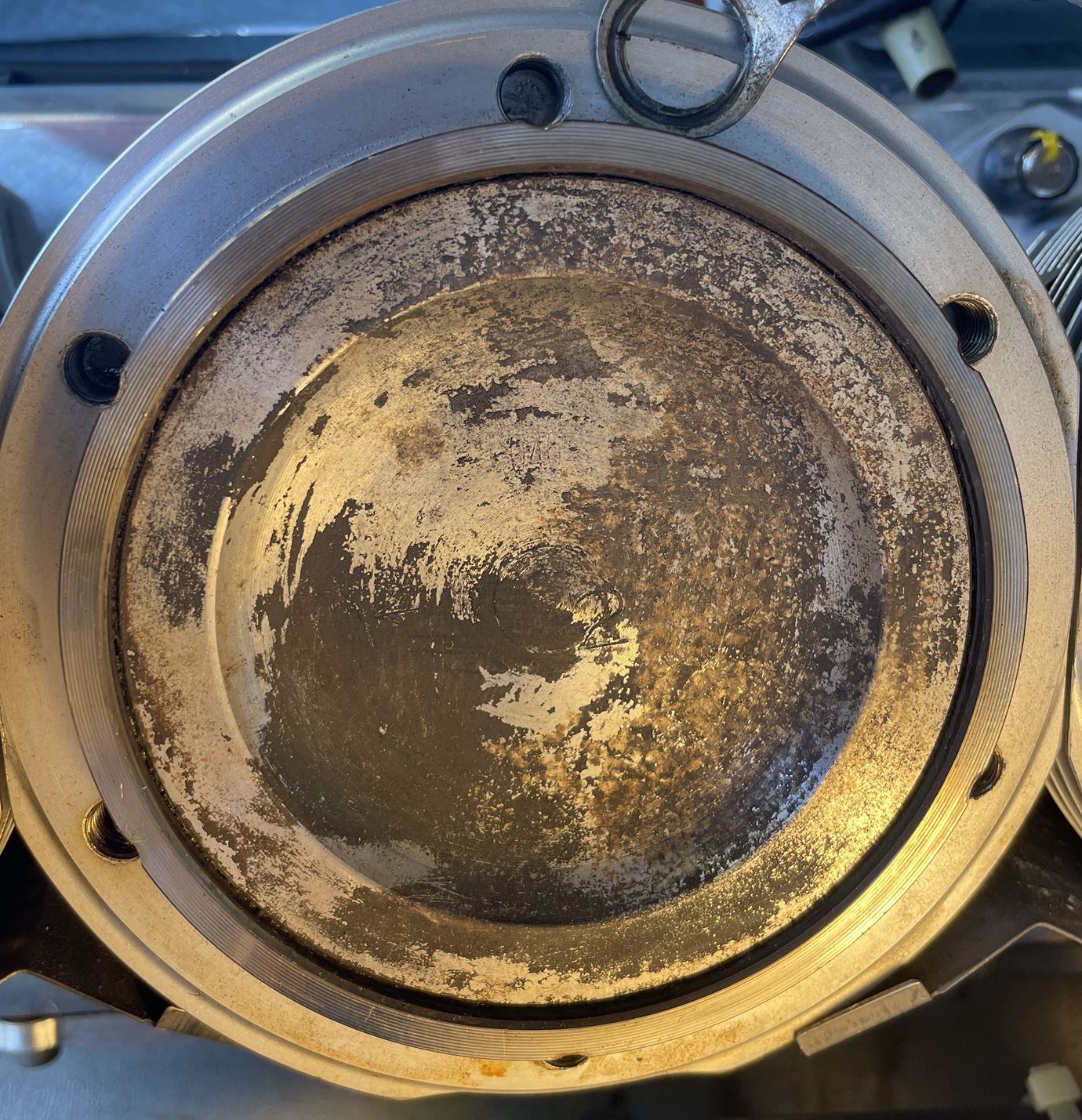

I decided some time ago that I was going to pull one or two heads at 200 hours and have a look inside to see how my LCH’s are fairing. I have 190 hours, so close enough. Since my CHT’s are pretty similar and not diagnostic (LCH’s), I have been focusing on my EGT’s to determine which cylinders are hot vs cool. Today I pulled number 6 head which runs as my coolest/richest usually around EGT 1200-1280 F. Here are the results. The combustion chamber had moderate buildups, as does the piston crown. The material appears to be carbon and lead phosphate (from the Decalin lead scavenger) or a mixture of the two. I use exclusively 100LL (with decalin). Here is a photo of both cylinder head and piston crown upon removal of the head. Good news is there is no sign of any leakage and no recession (Rotec LCH’s are high temperature silica doped cast aluminum, so would have to get close to 500 f to yield).

About 5 minutes with a piece of phenolic followed by a solvent rag, resulted in the removal essentially all of these soft buildups and then the head and piston crown looked like this.

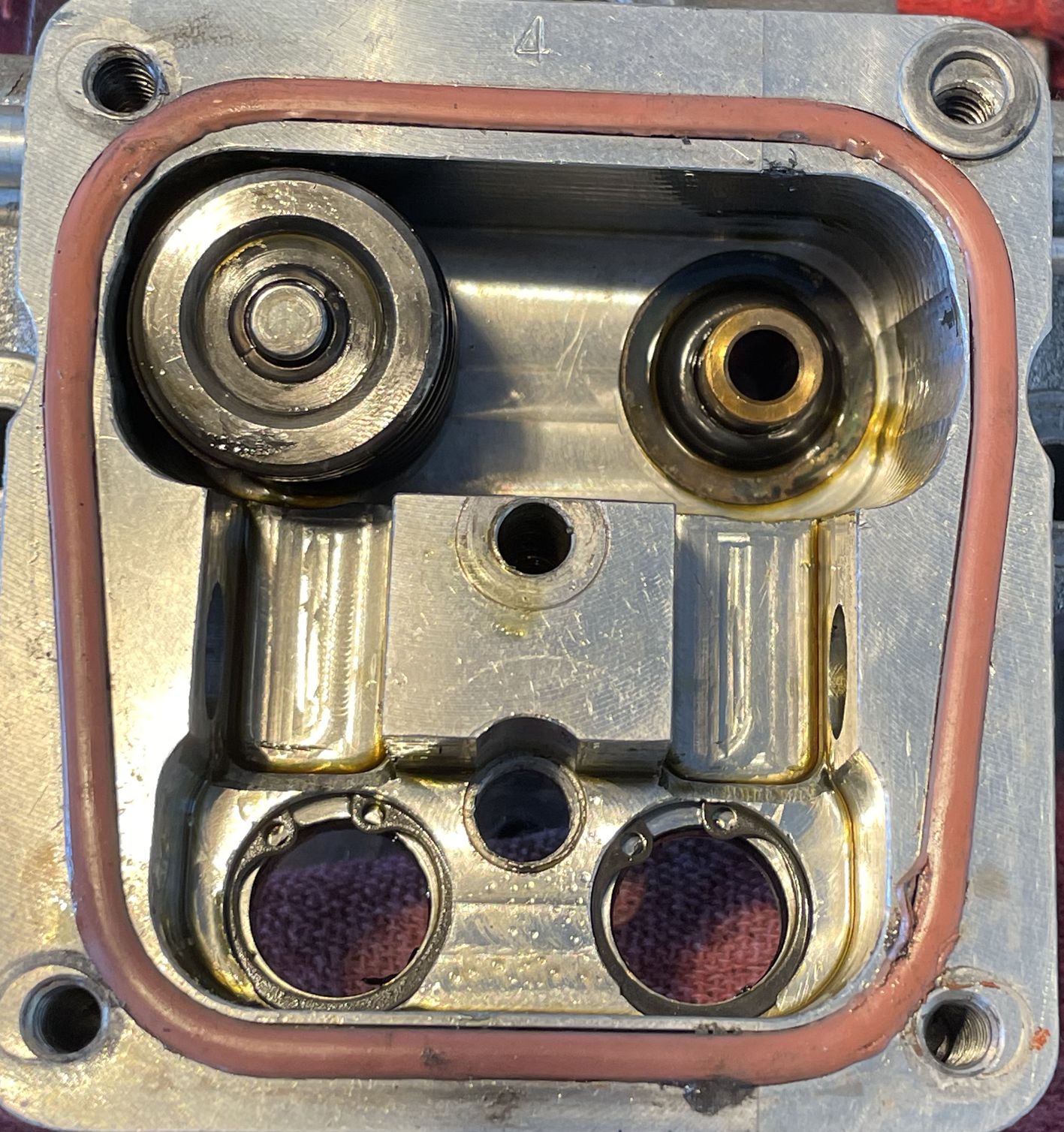

The deposits on the exhaust valve are more yellow-ish and are much harder. Takes sandpaper and scotchbrite to remove. I think this is lead borate. The piston cleaned up even better and shows no signs of detonation, or erosion or overheating. The rocker box looks fantastic. Essentially new. There are no deposits and the exhaust valve side looks as clean and new as the intake valve side. No deposits on the guide and no play at all of the valve in the guide. Again, like new.

Rocker bushings are in great shape (they are the Camit rockers that I installed with their solid lifter conversion kit). The lifter bushing and the contact surface with the rocker axle looks polished and new, so no problems there. The valve stem where the rocker arm face makes contact has a circular wear pattern. That is what you want to see, in order to know that the valve is rotating properly. I disassembled the valve and spring assembly on the exhaust side and this is what I found. All components clean with no evidence of heat or abnormal wear.

Exahaust valve had deposits below the guide. These were hard and took sandpaper and scotchbrite to remove. This is probably the lead borate that Mike Busch talks about resulting from leaded fuel. The first photo is before cleaning and the second is after sandpaper and scotchbrite. The valve does not look like it has had excessive heat. There was only a couple of mm of burned oil or varnish on the stem where it enters the guide and no buildup there. The rest of the valve was polished like new. Inside the guide was the same.

Valve seats and contact face on the valve looks good. Will probably lap it lightly before re-installing.

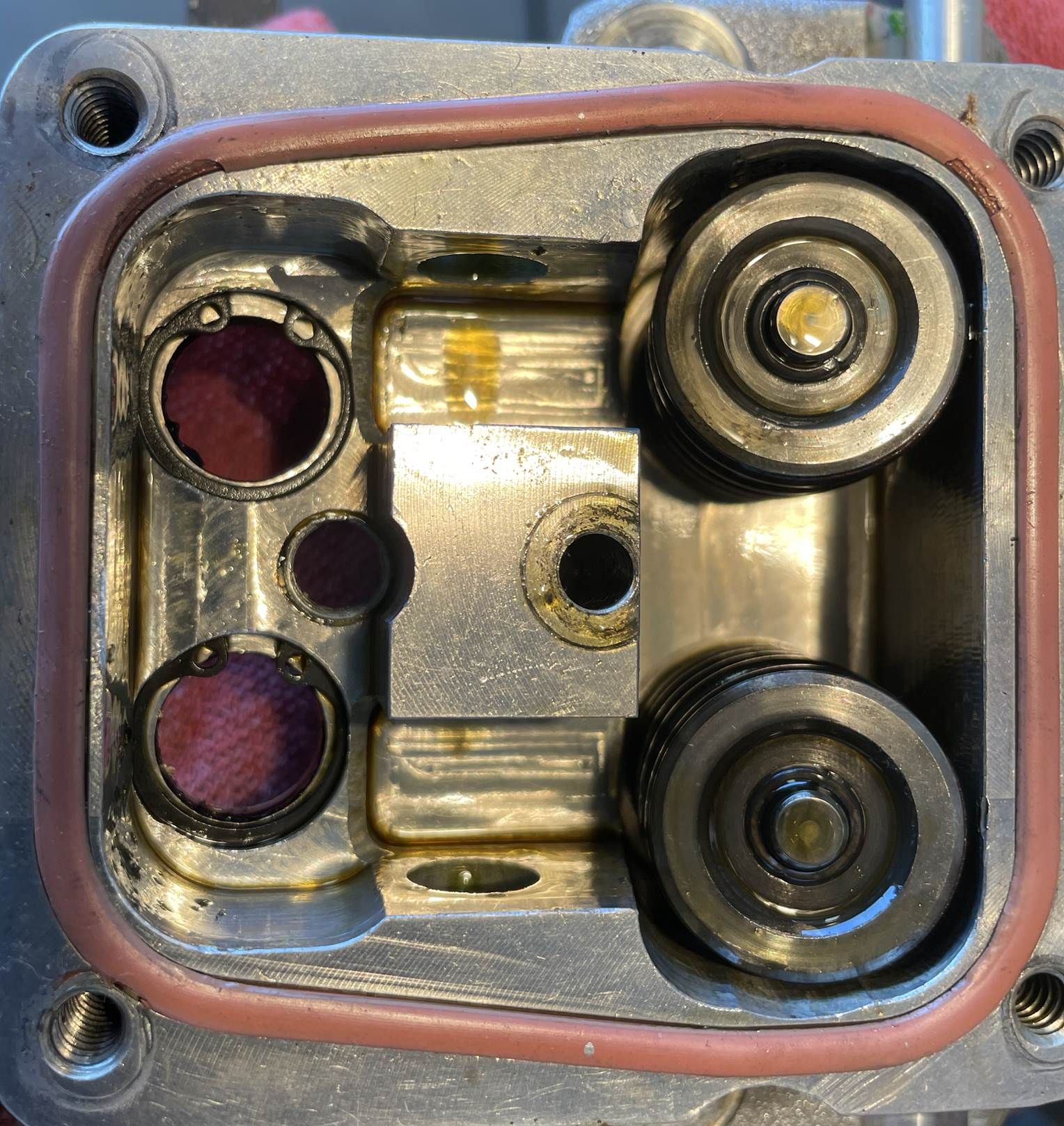

Took off the second cylinder head today (#4). This one is the hottest of the EGT’s running from 1380-1410 F, which is out of the recommended high range for the Jab. I am somewhat comfortable with this, since my heads are running very cool and have cooling internal to the heads and adjacent to the exhaust valve guide and seat. I am certain that my valve is running cooler than it would in the aircooled head. While removing the head, I did notice that I could wiggle the intake pipe that is connected to the manifold. Others are solid. I may have found why this cylinder runs hotter than the rest. I will seal that when I reassemble and see if it causes the cylinder to run a bit cooler.

The combustion chamber looked very similar to the cool head (#6) that I highlighted yesterday. The same type of deposits that were removed easily with a piece of phenolic and solvent rag. Here are the raw and cleaned photos of the head and piston crown. Moderate buildups and no evidence of leakage or head recision.

After cleaning they looked like this. Very similar to the cooler head. No evidence of detonation or abnormal heat, but some of the deposits in this head were a little more resistant to cleaning. Again the deposits on the exhaust valve were much harder and require sandpaper and scotchbrite to clean. I have decided to clean only the stem and leave the deposits on the back side of the valve, since they are probably providing a bit of insulation for the valve.

Exhaust valve had slightly more deposits on it than did the valve from #6. Same material. Cleaned up with sandpaper and scotchbrite.

Rocker box was clean and new looking, as was the valve guide. No play or wobble of the valve in the guide and no deposits internally.